Conformal Coating Systems

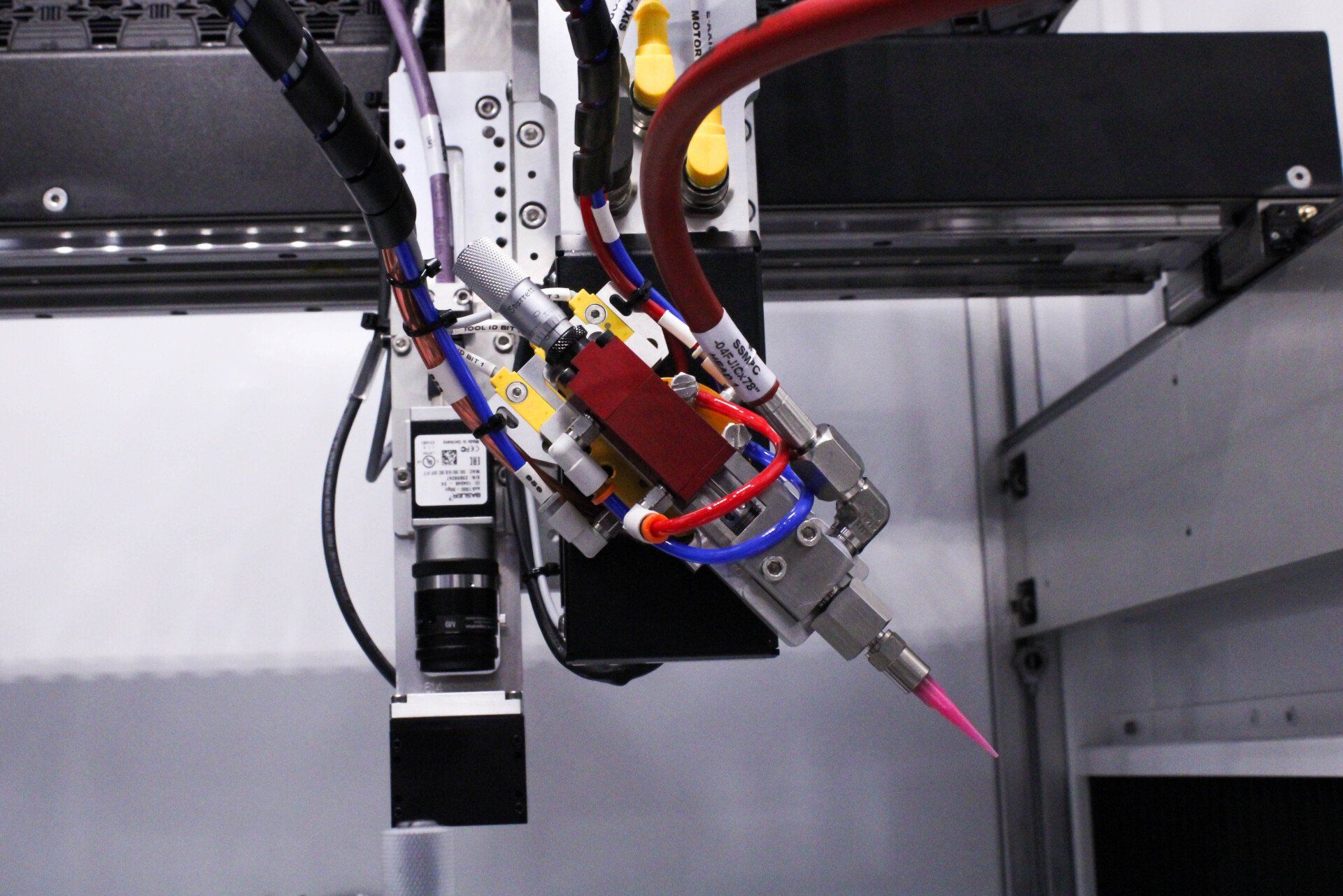

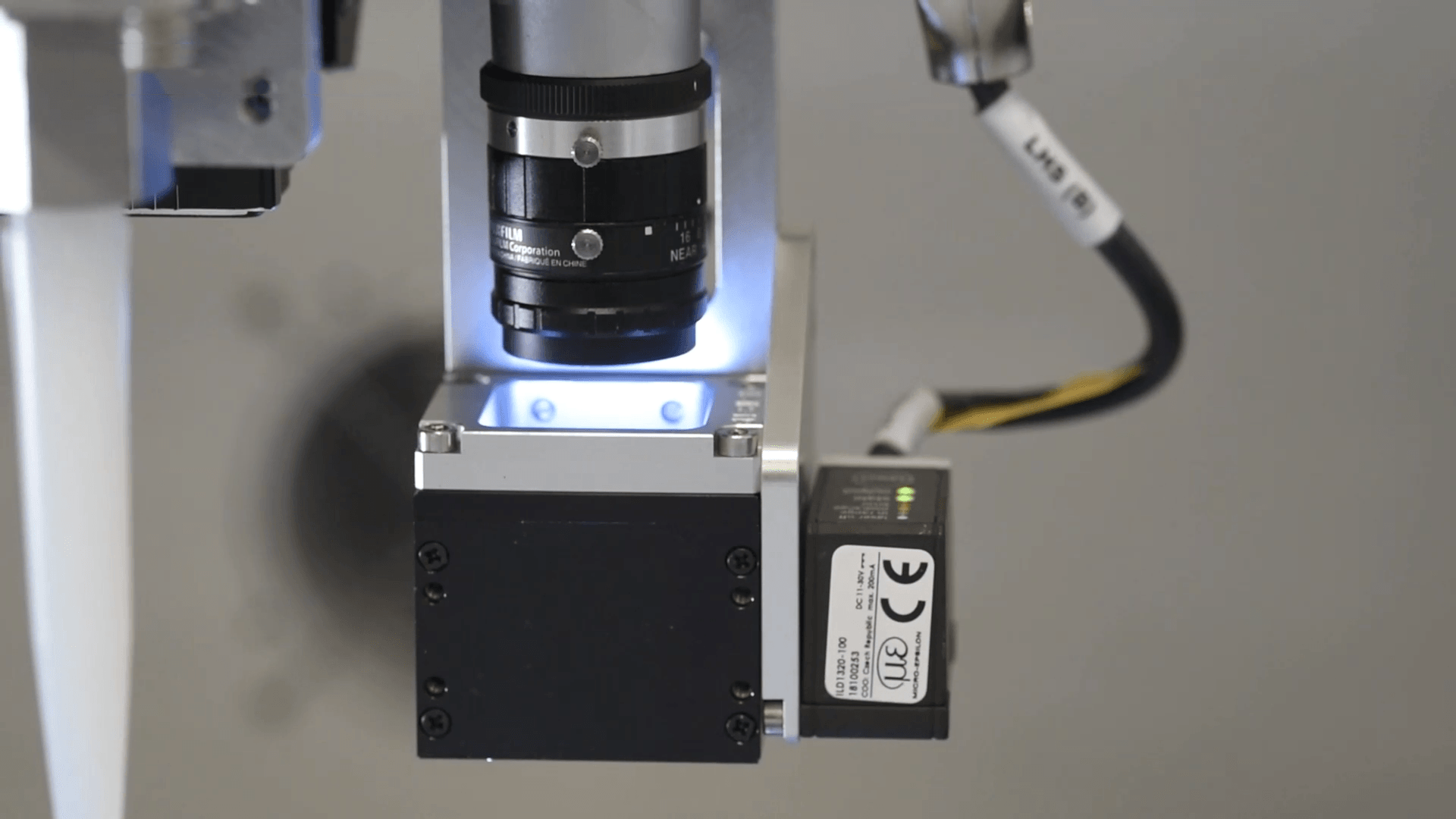

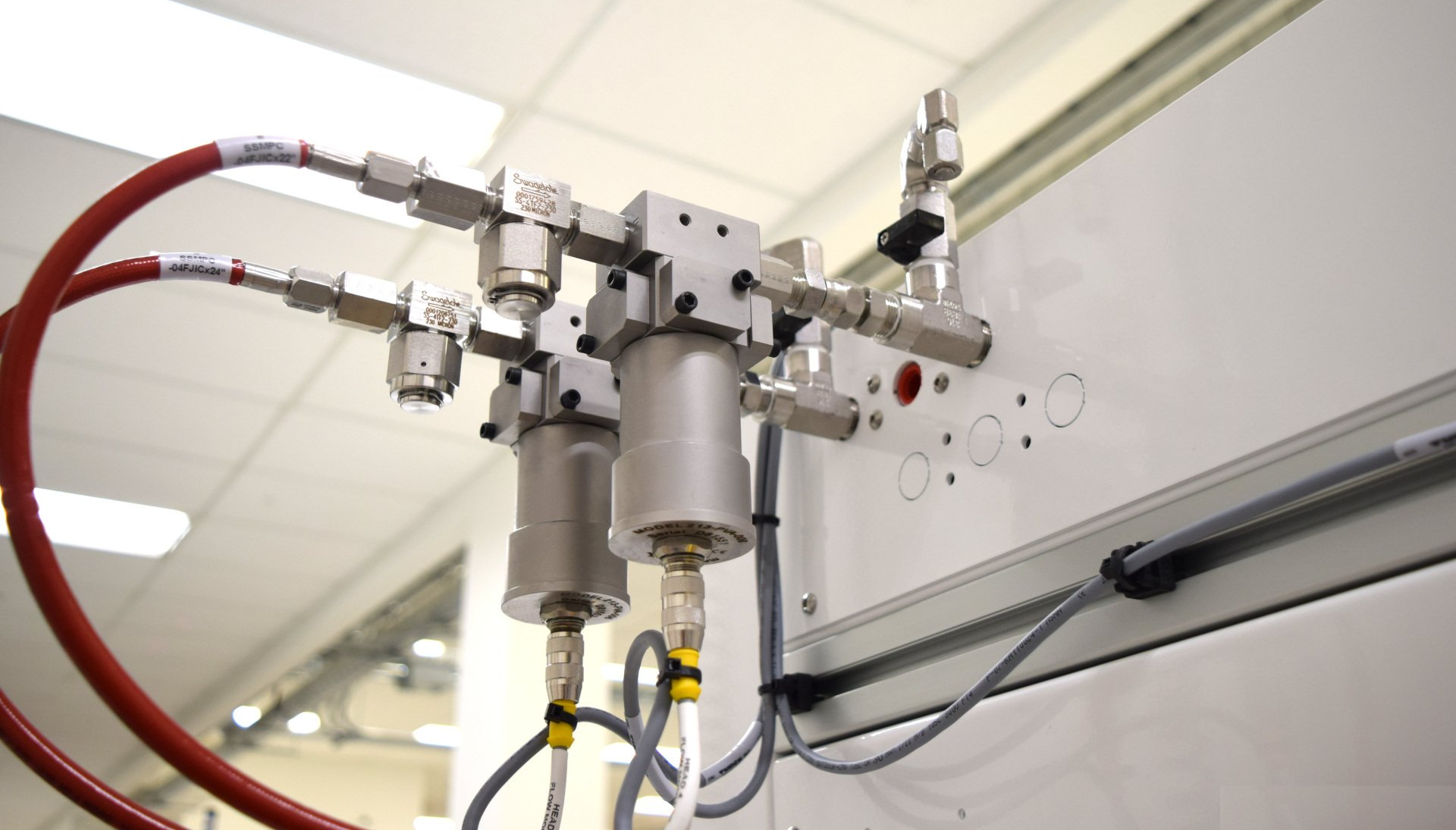

On ever smaller and increasingly densely populated panels, precision and process control during coating are crucial to apply the material in a controlled, uniform manner and without splatter. With its coating systems, PVA presents robust systems that reliably deliver repeatable results and are flexible in use at the same time. Innovative features ensure maximum precision and controlled material delivery for the optimum coating result.

DELTA 8

Compared to the Delta 6, the Delta 8 scores with an enlarged working area and is designed for maximum flexibility: The inline system masters diverse applications and can process a wide range of materials.

Further coating systems by PVA

Delta 6

The Delta 6 combines the principles of successful inline coating on a small footprint:

- Robust 3- or 4-axis motion platform

- Up to ±50° valve tilt and 360° valve rotation

- Process repeatability of ±25µm in X-, Y- and Z-direction

- Working area: 521mm x 485mm x 100mm

- Fooprint: approx. 85cm x 114cm x 160cm

- Closed-loop functions

PVA 350

The benchtop system PVA350 impresses with its precise appication, a enlarged working area and numerous features that are also used in the Delta 6 and Delta 8 inline machines.

- Robust 3- or 4-axis motion platform

- Valve tilt and rotation

- Optical Encoder-Feedback on all axes for highest precision

- Process repeatability of ±25µm in X-, Y- and Z-direction

- Working area: 365mm x 378mm x 101mm

- RS232-interface

Sigma

This extremely compact benchtop unit is ideal for the sporadic application of protective coatings and fits into any production environment:

- Robust 3- axis motion platform

- Can be equipped with up to 2 dispensing valves

- Process repeatability of ±50µm in X-, Y- and Z-direction

- Offline programming and image import: programs can be loaded via the integrated Wi-Fi interface

- Working area: 330mm x 300mm x 100mm

- 5" Touch-Display

Options and accessories

With additional rotation and tilting axes, automated tool change and process control tools, PVA offers a range of options for the individual configuration of its Delta 6 and Delta 8 inline systems.