Laser Marking

Realize long-lasting traceability with laser marking

In SMD production, a laser marker is used to apply codes or labels to the PCB (DPM, Direct Part Marking). These usually contain the unique serial number or other information with which the PCB can be clearly identified and are therefore an essential part of continuous traceability.

SmartRep offers the laser marker from YJ Link for the permanent marking of PCBs.

The advantages of the YJ LINK Laser Marker

Integrated Flip-Station

With the flip station integrated as standard, the YJ Link Laser Marker can be used to mark PCBs on both sides in just one process step.

Ghost Marking Function

The code can be projected onto the PCB in advance for precise placement of the marking, even on densely populated PCBs.

Readback-Function

Each lasered code is automatically checked by the system for readability and evaluated according to the criteria of ISO IEC TR 29158.

Secured traceability

With laser marking, the code is permanently applied to the PCB material, which has a number of advantages in terms of the legibility and durability of the code:

In contrast to a stick-on marking (label), a laser marking cannot peel off or fade. The marking proves to be extremely robust against mechanical influences such as scratching, which can make the code illegible.

Laser marking therefore ensures the permanent traceability of the PCB.

Fast, safe, clean

With an integrated turning station, ionizing and exhaust unit and a high-quality CO2 laser, the codes are applied quickly, reliably and cleanly. For full traceability right from the start, it is advisable to place the laser marker upstream of the line as a marking cell. This means that every process step can be tracked.

Frequently asked questions about laser marking

How does laser marking work and how small can a code be lasered? Do you need a laser safety officer to operate a laser marker?

We'll tell you!

How Laser Marking works

Material procesing with a laser follows a simple principle: The laser transfers energy into the material that is to be processed, which triggers a reaction based on the material. Therefore, a laser can ablate, engrave and oxidize metal, while plastics can be ablated, carbonized and foamed. A color shift is also possible. Because a color shift only needs a little energy, this method is most commonly used for marking PCBs.

Color shift in solder resist

In this process, the color pigments in the solder resist are deliberately destroyed by the laser, which becomes visible on the surface as discoloration (marking).

The color of the marking cannot be controlled by the intensity of the laser; the contrast between the marking and the background therefore varies with the color of the solder resist. In general, markings on green or blue PCBs result in a very good contrast, while markings on red PCBs have a lower contrast.

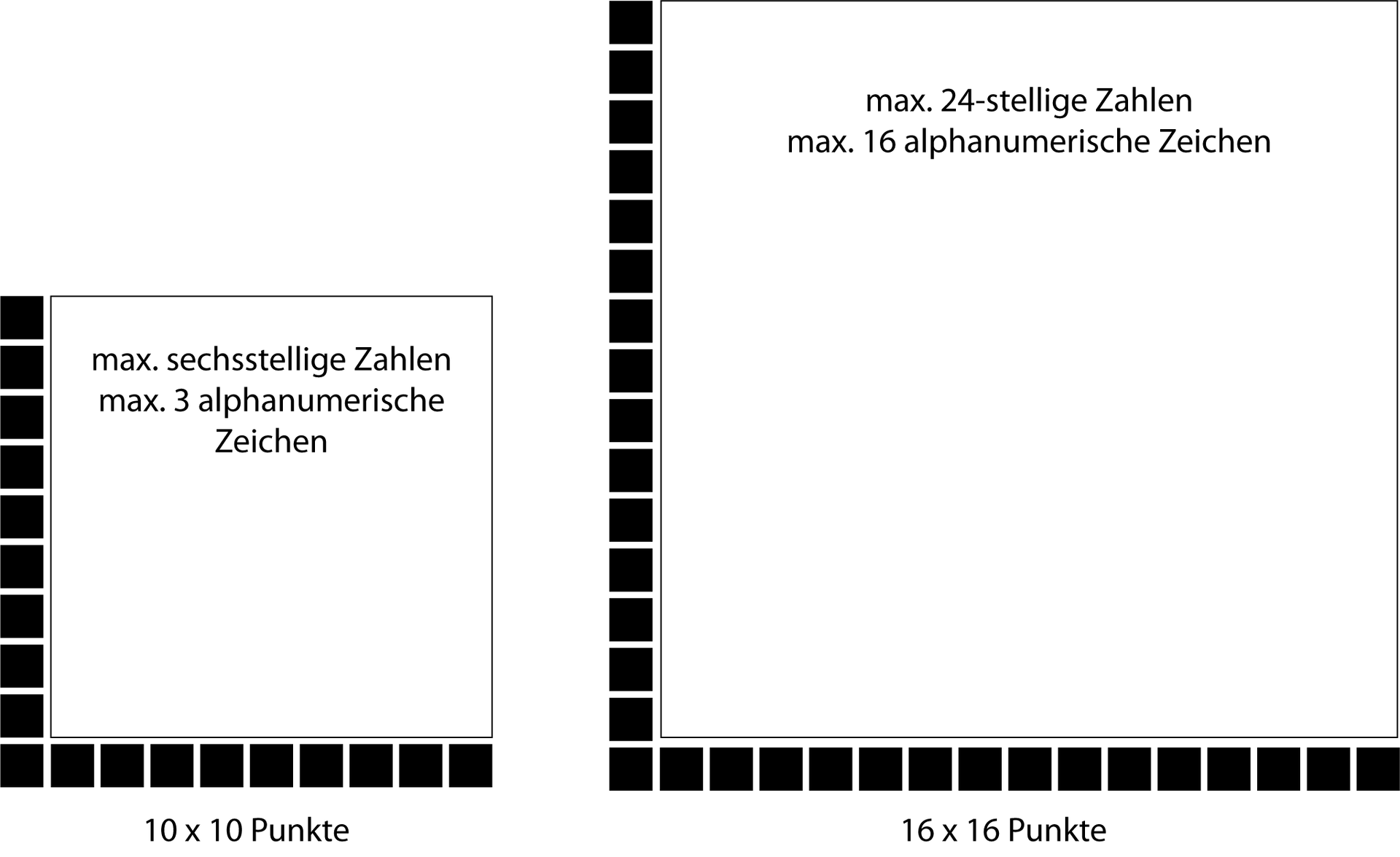

In order to be readable by standard scanners, a dot should not be smaller than 0.2 to 0.25mm. Since each Data Matrix code consists of at least 10 x 10 digits (dots), the recommended minimum size is 2mm x 2mm - even if smaller formats can be implemented with a laser marker.

10 x10 dots are the minimun size of a data matrix code

The final code size depends directly on the amount of coded information: A maximum of six-digit numbers or three alphanumeric characters can be stored in a 10 x 10 matrix. The more information to be contained, the larger the barcode.

More information can be stored in a larger code.

Do I need a laser safety officer to operate a Laser Marker?

Whether or not a laser safety officer is required to operate a laser marker depends on the design of the system.

Since YJ LINK's laser marker is completely enclosed and equipped with additional safety measures such as a door interlock, the system has a laser class 1 rating. A laser safety officer is therefore not required to operate YJ LINK's laser marker.

Barcode Grading - Classification according to ISO IEC TR 29158

The quality of 2D codes directly embedded in the printed circuit board is regulated by the ISO IEC TR 29158 standard, also known as "AIM DPM". The standard specifies various evaluation criteria that can be used to classify the quality of a code on a scale from "A" (very good) to "F" (very poor).

The criteria specified by the standard include pattern errors, contrast ratios, distortions and aspect ratio errors. With the YJ LINK laser marker, all codes are automatically checked and evaluated according to the criteria of the ISO IEC TR 29158 standard.