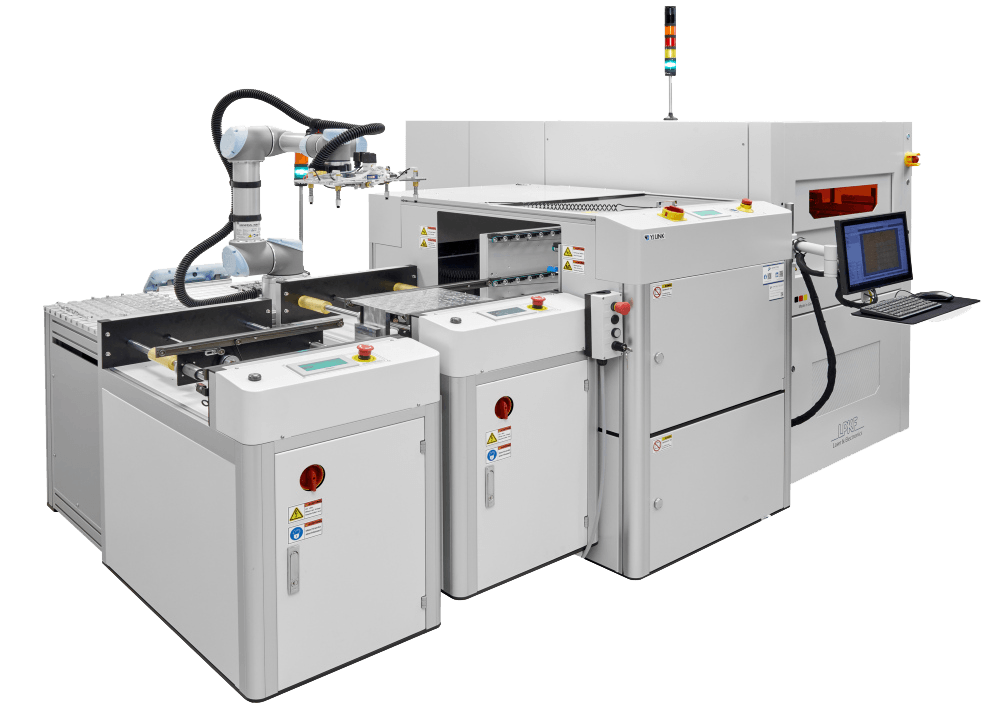

Modular automation:

LoadingMaster1000

Scalable

Handling with Cobot can be individually combined with various solutions such as conveyor belts, buffer systems, and magazine loading and unloading systems: the automation modules build on each other continuously and can thus be scaled precisely to meet any requirement.

Flexible

Individual gripper solutions ensure maximum flexibility when collecting the separated PCBs: The cobot can be equipped with a 1-point gripper, a multi-point gripper or an area gripper for fast loading and unloading of the substrate to be separated.

Efficient

Cobot automation stands for maximum efficiency with a small footprint: thanks to the buffer system, handling time can be significantly reduced by parallel loading and unloading of the panels.

The "all-in-one"-solution:

LoadingMaster 2000

Maximum performance

With the LoadingMaster, the focus is on speed and performance: The system combines all handling functionalities in a closed housing.

The axis systems enable extremely fast loading and unloading, while the lift systems ensure the continuous supply of material to the laser.

Autonomous & scalable

The LoadingMaster stacks empty containers such as blisters, boxes, etc. and independently picks up new material. This allows the system to operate autonomously for several hours.

The system can be equipped with various gripper solutions for fast loading and unloading.

Ergonomic

The height-adjustable drawer system allows blisters and boxes to be removed or placed in the system easily and ergonomically. Residual materials such as frame parts are guided directly out of the system at a separate position.

Intuitive operation

The software impresses with its simple operating concept: No programming knowledge is required to create the program, and user level management protects against unauthorized access. A digital twin ensures a smooth production process: All programs and parameters can be checked for errors and problems using the digital twin before they are executed by LoadingMaster.

LPKF'S most autonomous stand-alone solution:

LoadingMaster2100

Up to 4x longer autonomous

The LoadingMaster 2100 builds on the proven concept of the LoadingMaster 2000 and develops it further. This allows the system to work autonomously for up to 4x longer.

Highly specialised

The LoadingMaster 2100 is optimised for handling boxes with intermediate layers: The boxes are removed from the housing. The system automatically picks up new boxes; the filled boxes can be removed without interrupting the production process.

Fast

The changeover from empty to full boxes takes place via a rotating table with its own axis system, which reduces the cycle time to a minimum.