3D AOI by Koh Young

As world market and technology leader, Koh Young has over 15 years of experience and know-how in the field of 3D inspection. With extensive software tools for analyzing and monitoring the process, Koh Young systems provide more than just 3D measurement and enable targeted process optimizations. Suggestions from users are continuously incorporated into the development of the systems.

INLINE 3D AOI

Koh Young's AOI systems accurately measure components and solder joints in the third dimension and easily overcome challenges such as overshadowed components and PCB warpage.

Our customers are already convinced-

You too?

See the measuring accuracy of a Koh Young AOI with your own eyes during a demo - even directly on your own products!

Our 3D AOIs for the best process result

Zenith 2

The Zenith2, a perfected further development of the Zenith, impresses with powerful side cameras for optimal defect detection and features that ensure a smooth and controlled production flow.

- camera resolution: up to 12MP, 15µm

- FoV-size: up to 56mm x 56mm

- PCB size: up to 700mm x 690mm

Zenith

The Zenith measures components and the height of the solder flux exactly in 3D, independent of shadows or reflections.

- camera resolution: up to 8MP, 10µm

- FoV-size: up to 40mm x 40mm

- PCB size: up to 850mm x 690mm

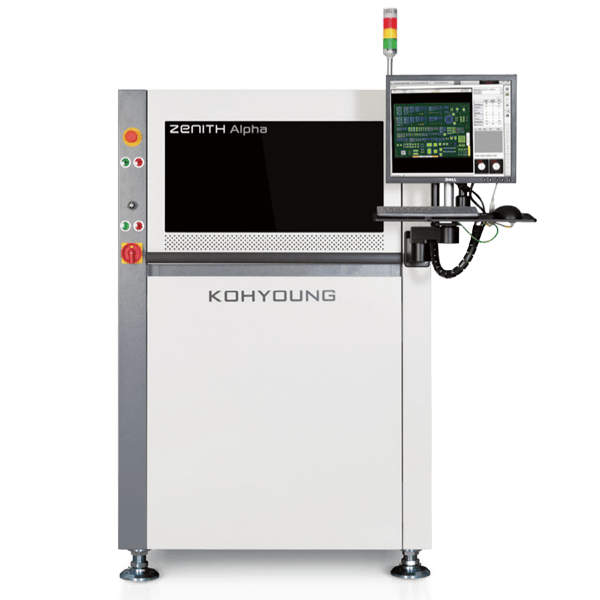

Zenith Alpha

The Zenith Alpha combines Koh Youngs measurement accuracy with speed, making it an ideal AOI for production lines with a high throughput. Tall components are no problem either.

- camera resolution: up to 12MP, 10µm

- FoV: up to 61mm x 46mm

- PCB size: up to 690mm x 690mm